What is Thermocouple and How Does it Work?

What is Thermocouple?

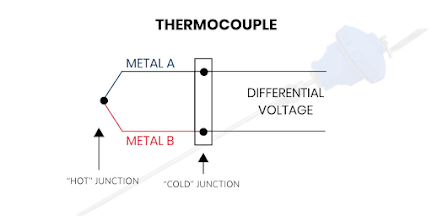

The thermocouple is a kind of temperature sensor that is made by joining two different types of metals at one end. The heat is applied to the junction of the metals after which a voltage develops across the metals which is in correlation with the temperature.

One end of the thermocouple is connected to the measuring junction, the body whose temperature is to be measured. The other junction is connected to the reference junction, the body with an unknown temperature.

The thermocouple takes reference from the measuring junction to measure the temperature of the unknown body. The robustness and cost-effectiveness of thermocouples make them applicable across a wide range of temperature measurements.

A thermocouple is available in many shapes and forms. Some of the commonly used styles are thermocouple probes, bare wire thermocouple, and infrared thermocouple. Determining the right kind of thermocouple is often very confusing. It is better to understand the functionality of the thermocouple before purchasing it.

Every thermocouple comes with a different technical specification whose understanding is important for purchasing and using it.

Thermocouples are widely used across industrial, OEM, and scientific applications. They are extensively used in different industries including the power generation industry, pharmaceutical sector, paper & pulp industry, oil/gas industry, cement industry, and biotech sector.

Everyday appliances such as stoves, toasters, and furnaces use thermocouples in their functioning.

How does it work?

Two different metals are joined to make a thermocouple. Both the metals after connecting form two junctions that are subjected to different temperatures. The difference in the temperature of junctions generates Peltier emf within the circuit.

The temperature at both the junctions should be necessarily different as the equal temperature will result in zero net currents flowing through the circuit. The generated emf in the circuit depends on the materials used as metals in making the thermocouple.

A device for measuring the emf/current flowing through the circuit is attached to the thermocouple. It measures the current flow which is generated by the temperature difference of the two metals in the thermocouple. The temperature of the reference junction is known and the other junction is unknown.

The output of the circuit is calibrated against the junction with the unknown temperature. Ultimately, the temperature of the unknown junction is determined using the thermocouple.

To measure the current, highly sensitive instruments are used as the emf developed in the circuit is very small. The most commonly used devices are voltage balancing potentiometer and galvanometer.

Types of Thermocouples

Thermocouples can be of many types with different functionalities, temperature range, durability, chemical resistance, vibration resistance, and application compatibility. Thermocouples of type K, type J, type T, and type E are known as the base metal thermocouples. The thermocouples of type S, type R and type B form the ‘Noble Metal’ thermocouples.

Conclusion

If you are looking forward to purchasing thermocouples then you can contact us. We are the leading thermocouple manufacturers of type S and type K thermocouples. Contact us today to get the best quality thermocouples to get the most accurate results.

Comments

Post a Comment